Interested in Infrastructure?

Get Infrastructure articles, news and videos right in your inbox! Sign up now.

Infrastructure + Get AlertsSewer systems allow communities around the world to manage wastewater and keep public areas clean, healthy and habitable. Sewer pipes, the conduits for the removal of waste, are the most fundamental piece of this essential infrastructure.

From the brick and mortar sewer pipes of the ancient Indus Valley to the high-durability PVC of the modern era, sewer systems have evolved over thousands of years. Today, sewer workers maintain pipes built to meet a range of environmental needs, available building materials and infrastructure demands.

Parts of a sewer pipe

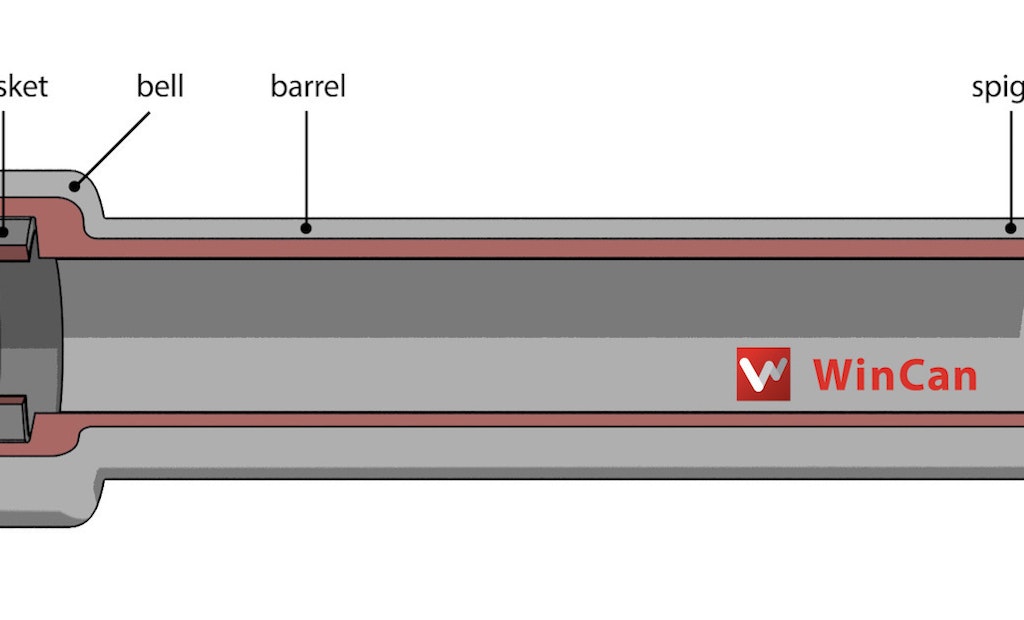

Four main parts make up most sewer pipes: barrel, bell, spigot and gasket.

- The barrel is of the body of the pipe, including the inner and outer walls.

- The connection of two sewer pipes usually consists of a bell and spigot joint, in which the spigot end of one pipe is the same diameter as the rest of the pipe, and the bell end flares to a slightly wider diameter to allow them to fit neatly together.

- A gasket is a ring, often made of rubber, that fits around the inside of the bell and helps seal the joint between two pipes. These gaskets are often attached by the factory before installation, but some pipe and gasket types require attachment on site. Often, this depends on the material used in manufacturing.

Materials

Pipes can be made of a wide range of materials. Standards have changed over the decades, but many older pipes are still in use and require regular maintenance. Rehab, cleaning and inspection teams must be well-versed in a variety of pipe materials to ensure they can accurately identify defects, weaknesses and potential solutions.

Concrete

An industry standard among contractors, concrete pipes can be reinforced, lined with clay, prestressed and/or polymer-coated. Concrete pipes are often made from raw, natural materials. While they require careful installation and regular maintenance, they resist many kinds of environmental damage and corrosion.

Plastic

Plastics like polyvinyl chloride (PVC), high-density polyethylene (HDPE) and acrylonitrile butadiene styrene (ABS) are lightweight solutions for wastewater infrastructure. Not only are they flexible and easy to install, but they offer resistance to corrosion, are sold in longer pipe sections than most other materials, and tend to cost less. According to the EPA, the pitfalls of plastic pipes are that their strength is sometimes affected by sunlight, making proper storage of plastic pipes more important than some other materials. They are also susceptible to chemical attacks, especially by solvents.

Clay

Clay pipes are still found in many residential sewer systems, though they are less common today than they once were. Vitrified clay pipes can be brittle and prone to cracking, but modern manufacturing processes have created technologies that are also highly resistant to most forms of stress and corrosion. They are limited to use in gravity sewers.

Metal

While cast iron was used in many underground systems in the early 1900s, a steel shortage during World War II turned more focus toward pitch fiber, also known as Orangeburg pipe. Later, ductile iron pipes replaced cast iron and became the preference for projects for which pipe strength and durability are needed above all else. However, given that it is heavy, expensive and prone to rust, cast iron is far less common today than it once was.

Sewer installation

Sewer pipe installation requires care to ensure long-lasting functionality and limit risk of collapse, corrosion or leakage. Typically, the process begins with digging a trench that covers the length and width of the intended pipe’s location. The trench bottom is covered with a bedding layer to protect the line against uneven sediment. Once the pipe is laid upon the bedding, the trench area surrounding the outer walls is filled with additional embedment material to secure it in place. Often, trench boxes are required as lateral support, protecting against cave-ins.

Sewer pipes might seem simple to the naked eye, but significant consideration goes into making them safe, effective and long-lasting. Knowing the composition, parts and installation methods of sewer pipes helps wastewater management professionals better understand the defects they are coding and make decisions on when and how to rehabilitate or replace them. This also helps determine how often certain sewer systems are inspected, as some pipe materials are more prone to corrosion and need more frequent inspection.

Understanding the type and nature of wastewater pipes is crucial to accurate assessment and maintenance. Learn more about the observation catalogs and coding standards used to evaluate pipes of all ages and materials in WinCan’s free white paper, “How Observation Catalogs Transformed Sewer Inspection.”

Visit the WinCan Storefront