Interested in Trucks?

Get Trucks articles, news and videos right in your inbox! Sign up now.

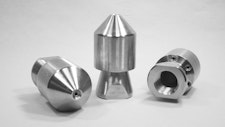

Trucks + Get AlertsSewer cleaning nozzles are designed for specific applications, including clearing blockages, removing heavy sediment, cleaning radiuses, and removing grease and roots. There are nozzles that change from penetrating to flushing, rugged nozzles that traverse even the most irregular paths, specialty nozzles that can quickly chew through roots, and nozzles that can churn through concrete and minerals.

Knowing how nozzles work — and understanding pressure and flow — is an essential part of the job. Selecting the right nozzle saves time, money, water and fuel, and maximizes performance and productivity.

Standard rodder nozzles

There are hundreds of nozzle types available for a variety of purposes, but a few key standard nozzles are essential for every sewer cleaning professional:

- Larger, heavier general-purpose nozzles are suited for cleaning and forward thrust capability in 8-inch and larger lines.

- Penetrator nozzles in 15- and 30-degree angles are suited for cleaning, penetrating and unblocking lines plugged with sand, dirt, grease and other accumulations on pipe walls.

- Sand nozzles in 15- and 30-degree angles are suited for cleaning, penetrating and unblocking lines plugged with sand and grease.

- Sanitary nozzles in 15- and 30-degree angles are suited for loosening debris, and cleaning grease and other debris in larger lines and running long lines.

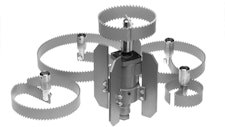

- Root cutter nozzles are suited for cutting roots, grease and scale in a range of pipe sizes.

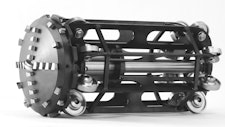

- Milling cutter nozzles are suited for tougher jobs, including clearing protruding taps, failed liners or mortar.

- A large nozzle with a guide fin keeps the nozzle centered in a pipe during cleaning and prevents the nozzle from wandering into a lateral.

Penetrator nozzles in 15- and 30-degree angles are suited for cleaning, penetrating and unblocking lines plugged with sand, dirt, grease and other accumulations on pipe walls.

Sand nozzles in 15- and 30-degree angles are suited for cleaning, penetrating and unblocking lines plugged with sand and grease.

Sanitary nozzles in 15- and 30-degree angles are suited for loosening debris, and cleaning grease and other debris in larger lines and running long lines.

Root cutter nozzles are suited for cutting roots, grease and scale in a range of pipe sizes.

Milling cutter nozzles are suited for tougher jobs, including clearing protruding taps, failed liners or mortar.

A large nozzle with a guide fin keeps the nozzle centered in a pipe during cleaning and prevents the nozzle from wandering into a lateral.

Pipe diameter

Cleaning 3- to 6-inch sewer lines generally requires a debris-removing nozzle. For pipes in the 8- to 15-inch range, rounded nozzles with four to eight jets are ideal. For pipes larger than 15 inches, a bottom cleaner nozzle is required. Removing debris in larger lines requires a nozzle and sled combination, along with a bottom cleaner.

Orifice angles

When selecting a nozzle, the operator should understand jet angles and their impact on the job.

- Jet angles in the 0- to 10-degree range are ideal for thrust to propel a nozzle up the line.

- Jet angles in the 15- to 20- degree range deliver more thrust and are ideal for cleaning the pipe wall, propelling the nozzle and moving debris on long runs.

- Jet angles of 30 degrees deliver more cleaning power and scouring action.

- While jet angles in the 30- to 45-degree range provide less thrust, they are ideal for cleaning pipe walls.

Servicing nozzles

Over time and with extended use, even the most efficient nozzles wear down, compromising pressure and performance. Be alert for the following signs of wear, which require immediate service and/or replacement:

- Wear rings (where applicable) are worn down

- Breached orifice, retainer or chamber area

- Noticeable leakage from areas other than the orifice

Vactor Manufacturing offers a complete line of nozzles for every sewer cleaning job. If you need assistance specifying or ordering nozzles, please contact your nearest Vactor dealer or visit www.vactor.com.