Many wastewater system managers focus on pipelines. But manholes can be an even greater source of problems, in some extreme cases contributing up to 90% of inflow and infiltration in a system. And as they’re easier to access, manholes are generally less expensive to fix. But to repair them, they must be inspected.

Traditionally, inspecting manholes was a tedious process performed by a worker who climbed down the manhole with a flashlight, a camera and a clipboard. He would look at the walls and identify issues visually. This process is dangerous, time-consuming and prone to mistakes and missed information. Now, many cities are turning to manhole inspection cameras like the Cleverscan.

Inspect smarter with CleverScan

As inspection technology advances, the types and quantity of data gathered from an inspection grow. As with any changing technology, some users may find themselves at a loss when it comes to understanding their manhole data and utilizing it. Instead of video footage, manhole inspection data produces, most often, a full, high-res scan of the interior of the manhole and a point cloud for 3D applications. Let’s break these pieces down for a better understanding of what they provide.

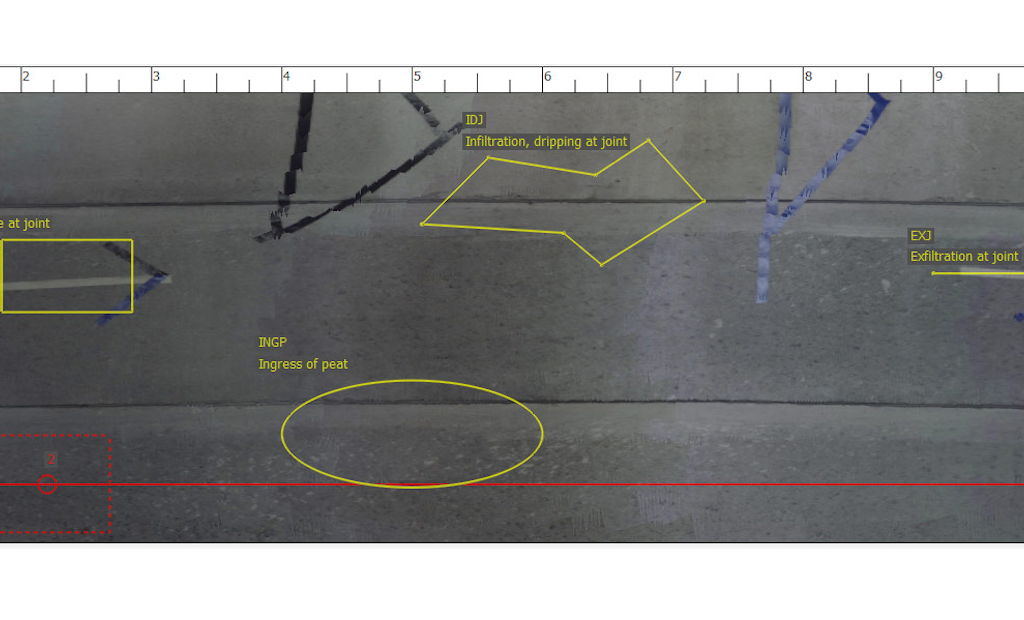

- Hi-res scan: A high-resolution scan of the manhole is simply a picture of the interior of the manhole. This photo shows every inch of the manhole wall. It can be reviewed quickly to gain a baseline understanding of the condition of the manhole, or it can be studied intently and coded with NASSCO’s MACP to quantify the condition.

- Point clouds: Point clouds are sets of data points in space and are gathered by laser scanning devices. They provide a digital, 3D model of the geometry of the manhole. They can be used to detect deformation and design manhole liners.

The process for gathering manhole data can also look very different from the pipeline inspection process. With software like WinCan, operators can easily gather this data in an MACP-compliant report for supervisors and engineers to assess and plan rehabilitation efforts.

Rapid, easy and MACP-compliant

To do so, the operator must first create an MACP project in WinCan VX software. (This software comes standard with all Cleverscan systems.) Launch the Cleverscan module from within WinCan VX and initiate the scan. Once the scan is complete, it will autosave in WinCan. Then the end user, whether an operator, supervisor or engineer, can code the manhole defects using MACP.

This software, combined with the Cleverscan manhole inspection camera, provides wastewater operators with a fully compliant report and an MACP data set that can be imported into other MACP-certified software. With the addition of a cloud storage platform like WinCan Web, reports can be securely shared with the click of a button. Access can be given to a single person or team.

Together, WinCan VX and Cleverscan provide a simple, streamlined workflow for gathering inspection data, coding it and sharing with relevant stakeholders. When you’re ready to see firsthand the simplicity of manhole inspections with Cleverscan and WinCan,

Visit the Envirosight Storefront