In the demanding world of fleet management and maintenance, efficiency and reliability are non-negotiable. UNDERHOOD rotary screw air compressors have been proven in the field for almost 30 years, delivering reliability and performance, powered directly by the service truck or van’s engine.

Fleet managers and mechanics across North America continue to make the switch from tow-behind and above-deck air compressors to UNDERHOOD for its benefits in the field.

Why choose UNDERHOOD?

Engineered for the harshest environmental conditions and most unforgiving climates, UNDERHOOD air compressors offer a level of performance and durability that tow-behind and deck-mounted models simply can’t match.

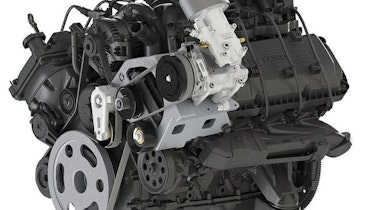

UNDERHOOD air compressor systems mount directly in the vehicle’s engine compartment, providing high performance, according to Mike Pettigrew, marketing manager at VMAC. “These North American designed and manufactured compressors offer incredible air volume at 100% duty cycle, and customers have relied on them for over 20 years to work in the most extreme climates and conditions.”

Application engineered for your fleet

VMAC’s team works closely with OEM engineers to ensure that each compressor integrates seamlessly with new model year vehicles, including Ford, RAM, GMC/Chevrolet and International work trucks, along with Ford, Mercedes-Benz and Freightliner service vans.

“Collaborating with major OEMs ensures each UNDERHOOD compressor fits perfectly, allows easy installation and maintenance, and preserves the vehicle warranty,” Pettigrew says. “VMAC’s vehicle-integrated systems stand out from the competition’s underdeck systems by eliminating potential alignment issues, added costs and the need for extra parts.”

Four models to choose for your work

The UNDERHOOD lineup includes four robust models: UNDERHOOD40 Truck Series, UNDERHOOD40 Van Series, UNDERHOOD70 and UNDERHOOD150.

The UNDERHOOD150, the most powerful model, produces up to 110 cfm, capable of powering heavy-duty tools like jackhammers, trenchless piercing tools and rock drills. This makes it an ideal choice for utility workers, construction crews, municipalities and others who need to operate large tools without sacrificing valuable vehicle deck space or the hitch.

Boost payload, reduce maintenance

UNDERHOOD compressors help reduce gross vehicle weight by up to 1,900 pounds. Weighing between 62 and 200 pounds, these lightweight systems enhance payload capacity and overall vehicle efficiency.

Additionally, the compact design of UNDERHOOD air compressors frees up to 80 cubic feet of space compared to traditional utility mount compressors, allowing for more tools and a cleaner vehicle appearance.

Each UNDERHOOD system is designed to operate at a 100% duty cycle, meaning no waiting for air. This feature is crucial for continuous drilling, hammering or any other demanding task. The increased productivity of UNDERHOOD air compressors is especially appealing to fleet managers.

“Servicing your UNDERHOOD air compressor is as easy as an oil change,” Pettigrew says. “There’s no extra engine to maintain, saving both time and money.”

Always on the job

Many fleets choose UNDERHOOD for its convenience. With the air compressor always on your truck or van, there’s no need to return to the shop to hook up the tow-behind. This frees up the hitch and eliminates the extra insurance and maintenance costs of an additional engine.

“With UNDERHOOD, you never have to worry about leaving a compressor behind or realizing it’s back at the shop,” Pettigrew says. “If your vehicle is there, so is your compressed air.”

VMAC has been a leading air compressor manufacturer in North America for over 35 years. VMAC’s mobile air compressors and multipower systems have earned a reputation for extraordinary design, build quality, durability and reliability in extreme conditions among operators and fleet managers worldwide.

250-740-3200 | sales@vmacair.com | vmacair.com