Are you frustrated with long lead times for mobile air compressors? VMAC has the solution: UNDERHOOD air compressors are ready to ship within 10 days.

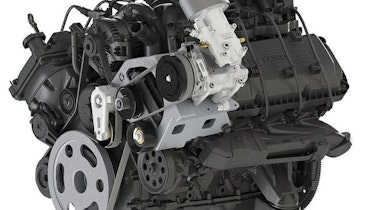

UNDERHOOD systems are engine belt-driven rotary screw air compressors that are installed in the engine compartment of a truck or van. These innovative air compressors are exclusive VMAC engineered products and specifically designed for OEM’s Ford, RAM, GMC, Chevrolet, International and Mercedes-Benz Sprinter service vehicles.

The design process includes cooperation between the OEMs and VMAC, as each UNDERHOOD air compressor system is created for a particular vehicle make and model. The relationships behind these collaborations span 25 years, ensuring UNDERHOOD systems perform optimally while keeping the vehicle’s OEM warranty intact, according to VMAC.

In-house assembly

After designing UNDERHOOD air compressors with the OEMs, VMAC teams begin engineering, manufacturing, testing and assembling the air compressor systems entirely in-house. VMAC controls the entire manufacturing process at its North American facility, which includes a foundry, machine shops, fabrication shop, quality labs and assembly.

This vertically integrated manufacturing ability has been particularly advantageous in recent months as supply chain issues have created significant challenges for air compressor manufacturers. While lead times for deck-mounted air compressors extend for months, UNDERHOOD systems continue to ship out to customers in less than two weeks.

These short lead times are highly desirable for major North American fleet customers requiring onboard air to complete their service truck and van builds, and it’s one of the many reasons VMAC has sold over 25,000 UNDERHOODs to date.

Saving space

The four UNDERHOOD models — UNDERHOOD40-Truck Series, UNDERHOOD40-Van Series, UNDERHOOD70 and UNDERHOOD150 — each offer significant space savings on the vehicles.

The UNDERHOOD40 only requires 1.7 cubic feet on the vehicle deck or cargo area for a combined air/oil cooler and air/oil separator tank. Meanwhile, the UNDERHOOD70 and 150 systems are entirely contained to the engine compartment and do not require any deck space at all.

Another benefit to UNDERHOOD is the weight savings. Compared to an above-deck diesel engine driven air compressor, UNDERHOOD air compressors can save almost 1,000 pounds on the vehicle.

For example, the UNDERHOOD40-Truck Series air compressor system weighs only 62 pounds, while the UNDERHOOD150 air compressor is 48% lighter than competitive 100 cfm underdeck air compressors. Many municipal fleets prioritize lightweight equipment to decrease gross vehicle weight to meet weight regulations, improve fuel economy, or even downsize their vehicle class.

Other products

In addition to UNDERHOOD air compressors, VMAC’s product line includes direct-transmission-mounted PTO driven air compressors, above-deck gas, diesel and hydraulic driven air compressors, multifunction power systems, and OEM custom air compressor solutions.

VMAC’s mobile air compressor solutions enable fleets to reduce vehicle weight, load up trucks with more tools and equipment, and eliminate idling on the job site. Fleet customers and operators with VMAC air compressors enjoy less downtime and frustration on the job site, decreased costs and increased productivity.

VMAC has been a leading air compressor manufacturer in North America for over 35 years. VMAC’s mobile air compressors and multi-power systems have earned a reputation for extraordinary design, build quality, durability and reliability in extreme conditions among operators and fleet managers worldwide.

888-514-6656 | www.vmacair.com/underhood-air |sales@vmacair.com