Knowing the condition of underground sewer and water infrastructure is necessary to properly maintain essential services, and today’s CCTV inspection systems visually identify structural and maintenance issues like cracks, broken or collapsed pipe, infiltration, grease and roots as well as other issues.

Mainline inspection equipment is routinely used by municipalities, sewer/water districts and contractors for inspecting 6-inch and larger sanitary storm drain sewer pipelines. Smaller pipelines, 4-inches and under, are typically inspected with a push camera system and are accessed from the sewer clean-out or other entry points inside the house.

During an inspection, data collection software is used to identify assets as well as log observations of defects and maintenance issues. Pipeline Acescent Certification Program has a standard coding system, developed by the National Association of Sewer Service Cos. This tool is used for gathering common data that can be sorted by type of defect and severity of defect and allow an engineer to easily identify what pipes need to be addressed immediately, and how to address the defect.

Components and types

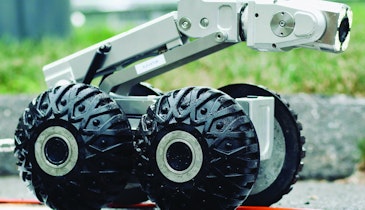

The basic components of a CCTV pipe inspection system are a camera or camera/transporter unit, power supply/control unit, and a reel-and-cable system.

The type of inspection system used is based on the size of the pipe and the conditions present in the pipeline. Inspection systems can include simple push camera systems that manually push through pipelines using a fiberglass reinforced cable; portable systems that can be wheeled into a tight-access area like a backyard or easement; and vehicle-mounted systems that are designed for inspecting thousands of feet of pipeline per day and can house all the equipment and supporting items.

Training and safety

To achieve maximum performance from inspection equipment, quality training is a must. Factory trainers or certified trainers are the best solution to receive proper training of operation and maintenance of the equipment.

Depending on the user’s experience, a mainline system training would take one to two days, and if additional equipment was purchased like a float system or a lateral launch system, an additional one to two days may be needed.

Sometimes breaking up the training into multiple visits can be beneficial to allow the operator to get familiar with one aspect of the system first — like the standard mainline camera and transporter — before coming back to learn about another product like a lateral launch system.

If you have employee turnover it is always a good idea to have a trainer do a refresher or a new training session to make sure no bad habits are passed along.

Subsite Electronics provides underground construction professionals a comprehensive suite of electronic products for the sewer/water industry, including utility locators, HDD guidance equipment, utility inspection systems and equipment machine controls. By using innovative technologies, extensive market feedback and outstanding customer support, Subsite has established itself as a premier source of electronic technology to support the installation, maintenance and inspection of underground pipe and cable.

800-846-2713 | info@subsite.com | www.subsite.com