We’ve all done it — bought something on the cheap and regretted it later. Price is a huge factor, but it is not the only thing worth considering when choosing your inspection equipment. What you really need is a piece of equipment that is going to last, a system that is going to perform to your requirements and keep you productive.

Cheap equipment that breaks down often or doesn’t work properly to begin with isn’t a bargain; it is a drain on your resources and time, according to a spokesperson from RapidView. “We don’t rely on off-the-shelf consumer products that may be discontinued next month. IBAK manufactures over 85 percent of our product components so we can guarantee quality, reliability and availability of spare parts 10 years down the road.”

Quality consultation matters

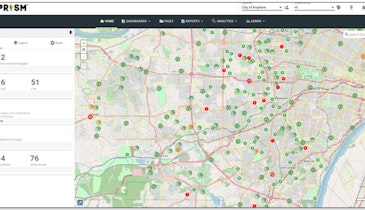

Municipalities looking to improve their cities with cost-effective equipment or contractors looking for reliable fleets to keep business moving can consider RapidView a partner. “As professionals and industry leaders, we and our dealers provide expert consultations regarding your goals and help you choose a trenchless technology to meet your needs and budget,” says the spokesperson.

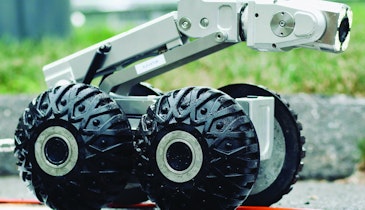

Since inventing pipeline cameras in 1957, IBAK has grown to be one of the largest and most technically sophisticated manufacturers in the industry, specializing in high-production sewer pipeline inspection equipment, including push cameras, mainline, lateral launch, high-definition, 3D mapping, 360-degree pipe and manhole cameras, portable systems and fully converted vehicles with complete system mounts.

“IBAK was first to market almost all the technology that our industry relies on every day, including the first camera, first color camera, first camera tractor, first pan-and-tilt camera, first data-logging software, first lateral launch, and the revolutionary 360-degree PANORAMO technology,” says the spokesperson.

The company distributes those products through an extensive and knowledgeable dealership network committed to providing quality customer service. “We understand that time lost due to repairs or poor training are detrimental to your productivity and bottom line,” the spokesperson says. “We offer a variety of completely free training programs for our customers throughout the year and provide you with the training, tools and support to conduct many repairs yourself. When faced with a more complicated repair, you can be assured that our service techs and regional service centers will repair your equipment quickly and have it back to you as soon as possible.”

RapidView was originally founded in 1991 as R&R Visual. The company then began developing and providing unique inspection solutions to the nuclear, petrochemical, industrial and municipal sewer industries.

800-656-4225 | sales@rapidview.com | www.rapidview.com